Project

Designer polymer composite tapes for surgical tendon repair

| Primary Investigator: | Renjie Liu |

| Co-investigators: | Remzi Becer |

| Hazel Screen |

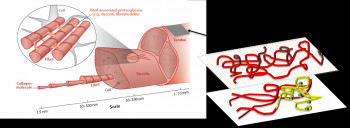

Tendons connect muscles to bone, creating the passive link to transfer active muscle contraction to bone, and facilitate movement. To provide this function, tendons must be strong in tension, and are thus collagen rich aligned fibre composite materials. Despite the tensile strength of tendon, ruptures are becoming increasing prevalent. Rupturing a tendon such as the flexor tendon is not just extremely painful but highly debilitating as it prevents locomotion.

Ruptured tendons are usually repaired surgically, where the surgeon makes one or more small incisions in the skin over the damaged tendon and sews the torn ends of the tendon together. The area is closed with sterile bandages or dressings, and the patient placed in a plaster cast or aircast boot to prevent excess loading of the injured site for periods of up to 4 months.

This time consuming repair process can be very costly, with patients often requiring significant periods of time off work. Furthermore, tissue in repair sites is generally inferior to healthy tendon tissue, and subsequently tendons are prone to re-rupture. At the same time, the adhesion formation during the repair process of the tendon also severely prevents the locomotion of the repaired site. These limitations have led to considerable interest in developing improved surgical processes, which will reduce healing time, and improve the resulting tendon repair site.

One such research avenue focuses around the use of synthetic mesh materials to augment the strength of the tendon repair site. As polymer chemistry has advanced, these meshes have become more intelligent, with many now steadily resorbing over time as the tendon heals, releasing growth factors into the repair site. However, whilst there have been some advanced in the field, an ideal solution is yet to be found. In particular, there are still key problems associated with attaching the mesh repair material to the tendon injury site.

Our project addresses these limitations, with the use of an advanced functional biomaterial that not only bridges the gap between tendon ends, but acts to glue the broken tendon ends together. First of all, we characterized membranes made up by electron spun with different composition to enable a difference in hydrophobicity of the membranes using tenocytes as a cell model. Cytotoxicity, cell activity as well as cell morphology on the membrane were characterized using Live/dead assay, alamar blue assay and cytoskeleton assay. The results shown a significant decrease in cell area on the electron spun membranes compared with cell grown on coated glass slides without influence viability and activity of cells, which shown the potential of using this materials in tendon adhesion prevention.

In future, we will change the composition of the membranes and compare the difference of cell behavior between different groups. Later on, we will functionalize the membranes with sugar molecule or growth factor to entitle the membranes with a glue function to tendon.